Transparent Fiber Reinforced Polycarbonate Resin Pellet

Product Features

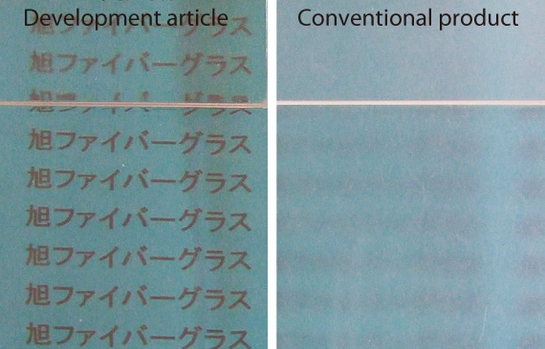

Through our efforts to develop new glass fibers, we successfully invented a revolutionary glass fiber reinforced polycarbonate resin compound that ensures transparency, a high level of rigidity and a low coefficient of linear expansion, even though it was once considered difficult to provide these three features.

The glass fiber used in this new compound prevents resin decomposition at the time of mixing polycarbonate resins. Alkaline elution was minimized by means of glass composition and surface treatment technology. In the full range of visible light, the glass is designed to have a refraction index close to that of resins.

The parallel light transmittance of a 2-mm-thick injection molded plate with a glass content of 10% as a result considerably increased from 13% to 74%. On the other hand, there is a remarkably low linear expansion coefficient of 45 ppm; dramatically lower than that of a polycarbonated resin molded product without reinforcing fibers, which is 70 ppm.

Major Applications

The product is used in infrared transmitting covers for indicators related to electronics & energy (E&E) and different types of highly design-conscious cases with a backside-printed or smoky look.